- KETAEBO Official

- 01/02/2023

What is hot melt adhesive web and fusible bonding web

Definition

Hot melt adhesive web is also called double-sided fusible interlining, or fusible bonding web, and there are many names. It is a hot-melt adhesive product made by a production process similar to non-woven fabrics. It is non-sticky at room temperature and sticky on both sides at high temperature. It is one of the derivative products of hot-melt adhesive and is non-toxic and harmless.

Hot Melt Adhesive Web With And Without Backing Paper

The hot melt adhesive web is usually without release paper, and it is directly placed between the two layers of materials that need to be bonded, and if you want it to have a layer of release paper, it can also be customized, and the width can be customized. The width is usually 1120mm. And if you want to customize 1500mm width, you need at least 20,000 meters of MOQ. We can also cut it narrow, such as 1cm, 1.5cm, 2cm, 2.5cm, etc.

For more introduction about hot melt adhesive web and fusible bonding web, please click here to view.

How to use the adhesive web:

Hot melt adhesive webs are available in different thicknesses, widths and lengths per roll, and the range of specifications customized for each model is also different. You can obtain this information by viewing the product links above.

Without backing paper:

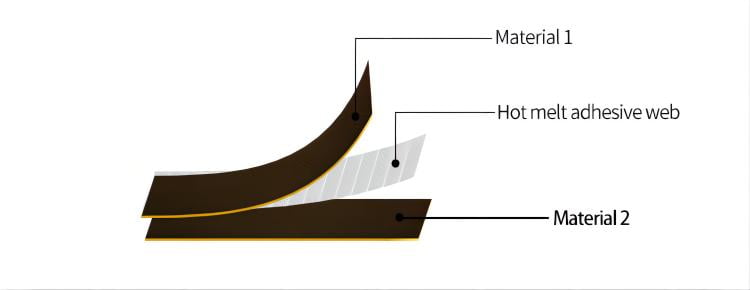

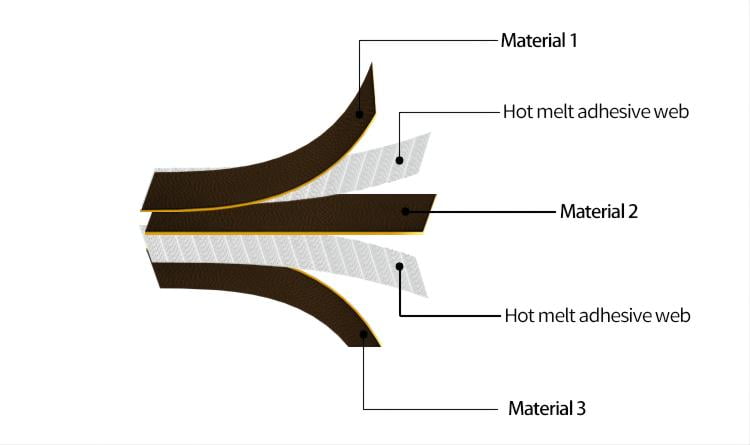

1. Cut the product into a specific shape according to your needs or use it directly.

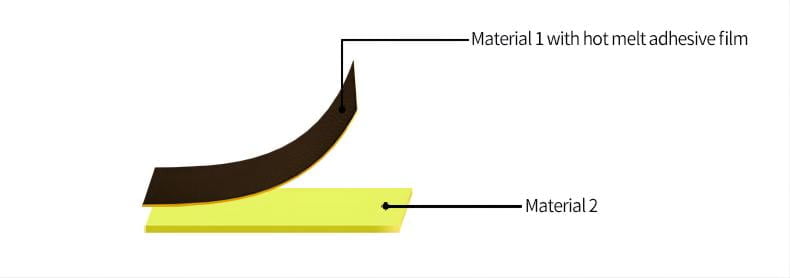

2. Place the hot-melt adhesive web between the two layers of materials that need to be bonded. The order of placement is material 1/hot-melt web/material 2.

3. Use an iron or professional pressing equipment to heat and iron on material 1 or material 2 sides (choose the material on the side that is easy to heat). Conduct heat to the hot-melt web in the middle and melt it to bond with material 1 and material 2 to complete the bonding.

Example: Plan view of double-layer material bonding:

Example: Plan view of three-layer material bonding:

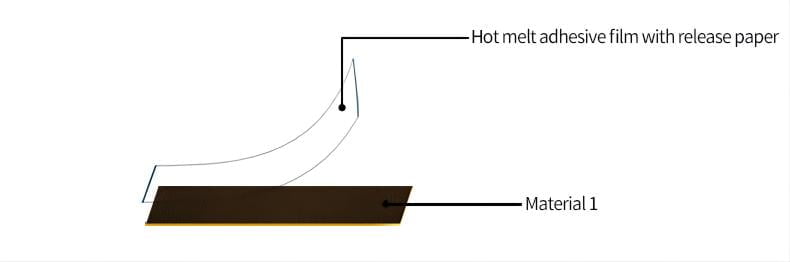

With backing paper :

1. Place the adhesive side of the hot melt adhesive web with the material to be bonded, with the release paper side facing up, and the order of placement is: release paper layer/adhesive film layer/material to be bonded1.

2. Use a relatively low temperature to heat the release paper side to make it adhere.

3. After cooling, peel off the release paper.

4. Align the glued material 1 with the material on the other side (material 2) that needs to be bonded. The placement sequence is material 1 / hot melt adhesive layer/material 2, and then use ironing equipment to bond. That is, the bonding industry is completed.

First bonding:

Second bonding:

Different Types of Hot Melt Adhesive webs

Related Products - Hot Melt Adhesive film:

Hot melt adhesive web can not meet the needs of some people. If you think it is too thin, consider using hot melt adhesive film products, as shown in the figure below. The hot-melt adhesive film is similar to the hot-melt adhesive web. Both use hot-melt adhesive as raw material, and they are both sticky on both sides, but we make it into a film shape. Its advantage is that it has better viscosity and the whole surface is full of Adhesive, and there are two types with backing paper and without backing paper.

Better tack and wash resistance, optional with or without release paper

Hot melt adhesive web & net

Online Chat

Contact Detail

-

[email protected]

[email protected] - +86 18641000189

- 18641000189

- +86 18641000189

- 825900650

- No. 48, Development East Road, Wanping Community, Wujiang District, Suzhou City, Jiangsu Province, China